Digital Solutions That Drive Manufacturing Success

Purpose-Built Digital Solutions for

Mid-Sized Industrial Firms

How Manufacturing Win

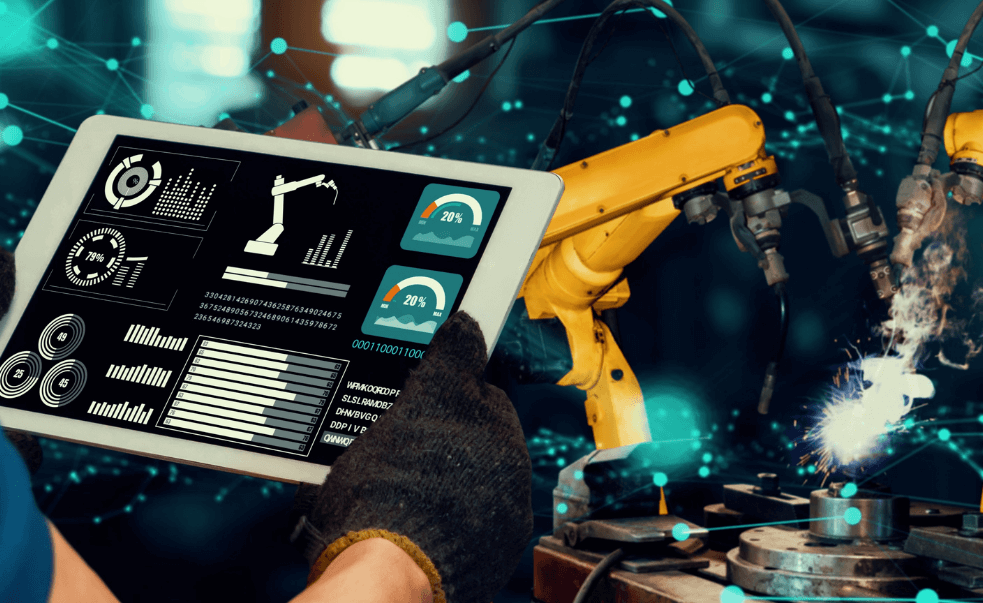

Real digital manufacturing isn’t about buzzwords—it’s about outcomes

Manufacturers today face a myriad of challenges: rising costs, inefficient processes, and the need to stay competitive. Outdated systems only add to the complexity. Infysion Technologies provides the tools and expertise to help manufacturers overcome these obstacles. With cutting-edge digital solutions like IoT, cloud computing, and advanced analytics, manufacturing businesses can streamline operations, make smarter decisions, and improve profitability.

By adopting these technologies, companies not only improve their efficiency but also unlock new opportunities for growth.

Our Industry Focus

Tailored IT Solutions for Every Manufacturing Sector

Outcomes That Drive Impact

Infysion helps manufacturers achieve visibility, agility, and sustainability through smart, scalable, and data-driven IT solutions

Delivering Success, Step by Step

Infysion Technologies delivers advanced digital solutions that drive real change in manufacturing operations. Here’s how these digital solutions have driven real change for manufacturers across industries.

Expertise That Drives Innovation

Infysion isn’t just another IT service provider. Our manufacturing IT services are designed to meet industry-specific challenges that improve operational efficiency, reduce downtime, and increase profitability.

Industry Knowledge

Industry Knowledge

Deep understanding of the challenges and opportunities within the utilities sector.

Customized Solutions

Customized Solutions

Tailored IT services that directly address the specific operational challenges faced by energy companies.

Results-Oriented Approach

Results-Oriented Approach

A focus on delivering measurable outcomes, such as cost savings, increased efficiency, and enhanced compliance.

Cutting-Edge Technologies

Cutting-Edge Technologies

Expertise in IoT, cloud computing, data analytics, and AI-powered solutions that are transforming the utility industry.

Tools and Technologies

Powered by Cutting-Edge Technology

Proven Results. Real Impact.

Real manufacturers. Real challenges. Real outcomes.

They have deep understanding of engineering challenges which has greatly enhanced our turbomachinery solutions. Their innovative approach to software optimization and real-time data integration helps us deliver actionable insights that improve the performance and reliability of our equipment, driving operational efficiency.

Ted Gresh

President | Oil & Gas Industry

Got Questions? FAQ

Can you integrate with our existing ERP or legacy systems?

Yes. Seamless integration is core to every deployment—especially for hybrid and legacy environments.

Is this only for large factories or big budgets?

No. We specialize in small to mid-sized manufacturers, with phased rollouts that are budget-sensitive.

How are Infysion’s IT services different from off-the-shelf software?

Everything is custom-tailored to your plant’s unique workflows, machines, and KPIs—not generic platforms.

What kind of digital programs do you build?

From predictive maintenance dashboards to energy efficiency systems—each program solves a real-world problem.

How quickly can we start seeing results?

Most clients start with a 4–6 week proof of value, and measurable outcomes show up within 30–90 days.

Is the solution secure and compliant with industry standards?

Absolutely. All deployments meet manufacturing-grade cybersecurity and regulatory compliance needs.

Industry Insights & Trends

The latest on innovation and industry trends

Digital Transformation for Smart Manufacturing | Infysion

Legacy systems have long powered the backbone of manufacturing. But as market dynamics evolve, these systems often become more of a liability than a strength. They were built for stability, not agility. For volume, not visibility. For continuity—not competitive edge. And in...

From Legacy Systems to Smart Operations: SMBs’ Digital Journey

Digital manufacturing is no longer reserved for global enterprises. Today, small and mid-sized manufacturing businesses (SMBs) are adopting digital-first strategies—and they’re seeing serious results. From increased throughput to reduced downtime and better sustainability tracking, digital manufacturing is turning traditional shop...

Driving Agility in Industrial Manufacturing with IT Solutions

In the world of industrial manufacturing, success depends on more than just machinery and manpower. Agility—your ability to respond quickly to market changes, customer demands, and production challenges—is the real game changer. But here’s the truth: most mid-sized manufacturers aren’t...